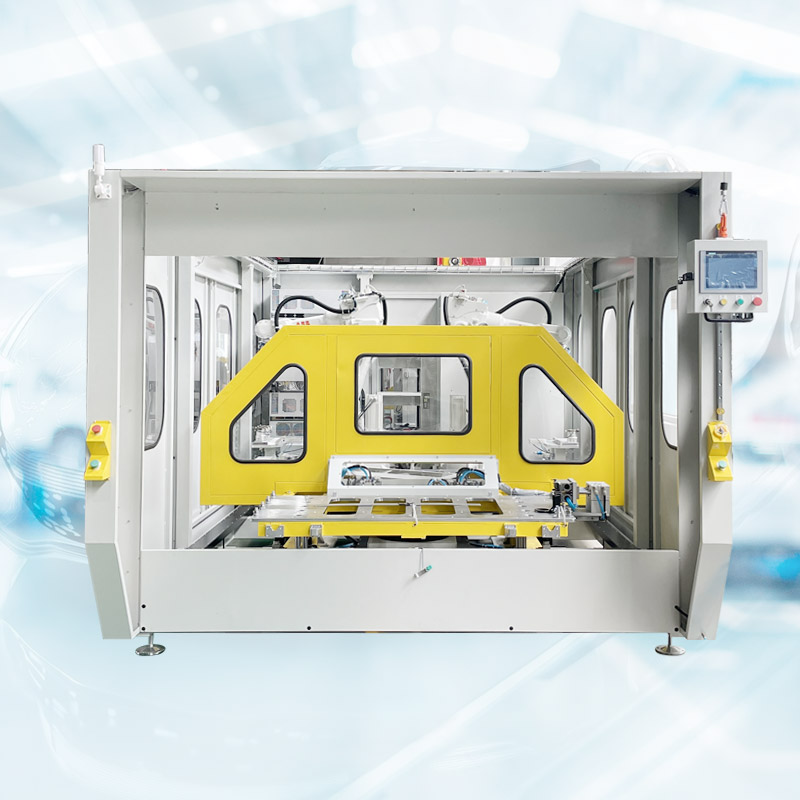

Car Inner Components Ultrasonic Robot Welder Workstation

NC Series Robot Ultrasonic Welder

● Versatile Product Welding:

Features a quick-change mold system that handles a wide range of automotive interior components. This enables fast switching between different products while maintaining quality.

● Stable and Efficient Cooling:

Precision temperature control system prevents material warping. The welding head performs consistently despite air pressure changes, ensuring quality welds during long production runs.

● Precision Welding Design:

Dizo robot ultrasonic welder uses cutting-edge amplitude technology for precise targeting and efficient energy transfer. The design reduces acoustic impedance, leading to better welds and lower energy use.

● High-Accuracy Welding:

Dual-layer sensor system with real-time feedback ensures precise welding. Dizo robot ultrasonic welder technology maintains consistent quality and microscopic positioning accuracy.

● Centralized Control System:

Dizo robot ultrasonic welder features a user-friendly computer interface for complete system control. The streamlined design makes operation simple while offering detailed monitoring and process control.

Request for Quote- Features |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Technology |

- Appilications |

- Reviews

Robot Ultrasonic Welder Features

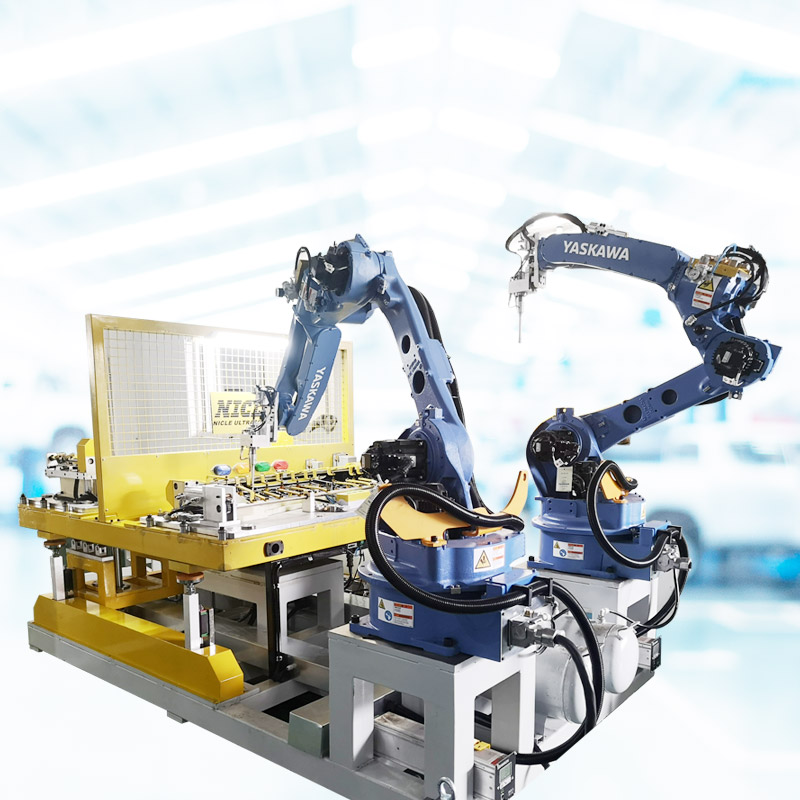

Robotic ultrasonic welding machine excel at joining automotive plastic components. Using high-frequency vibration, the robotic ultrasonic welding machine melt and bond complex, non-standard plastic parts with high strength and precision. This sophisticated welding method meets the automotive industry's rigorous standards while driving technological advancement.

In automotive interior manufacturing, the robotic ultrasonic welding machine handle diverse operations, from flexible bumper punching to sound-insulation welding. Dizo robotic automation enhances production efficiency, cuts labor costs, and ensures consistent weld quality. The robotic ultrasonic welding machine systems also perform supplementary tasks like radar bracket bonding, optimizing the production process.

Ultrasonic welding technology provides rapid processing, robust bonds, and superior sealing - essential qualities for car manufacturing. This efficient method outperforms traditional welding and bonding techniques, delivering clean, non-damaging operation without environmental impact. With ongoing technological progress and declining costs, these robotic ultrasonic welding machine systems are poised for wider implementation in car plastic component production.

We are Internationally Certified

Our robotic ultrasonic welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Purchasing Guide: Robot Ultrasonic Welder Workstation

We provide comprehensive robotic plastic welding solutions for automotive interior and exterior parts. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive interior sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the robotic welding techniques for the specific application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive interior samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected robotic ultrasonic welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the robotic ultrasonic welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the robot ultrasonic welder meets all standards.

-

STEP 9

Delivery and Installation

Deliver the robot ultrasonic welder and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the robot weld equipment.

Custom Dizo Robot Ultrasonic Welder Workstation Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the plastic welding process.

Professional Service Team

A professional 20-person service team ensures seamless robot ultrasonic welder installation and complete customer satisfaction.

Packaging for Robot Ultrasonic Welder

Plastic Welding Techniques in the Automotive Industry

Different welding applications demand specific approaches. Automotive companies often require a blend of robotic ultrasonic welding systems, hot plate welders, vibration welding machines, and hybrid solutions.

We specialize in integrating automated robot ultrasonic welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed ultrasonic sonotrodes and precise positioning allow us to tackle complex tasks, such as welding large car door panel, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Automotive Plastic Components Welding Applications

We provide specialized plastic welding solutions for automotive components that meet all production requirements.

Customer Reviews

Quote Now

Quote Now